Furthermore, we needed to achieve faster programming times for our aluminium mould tools hyperMILL was once again streets ahead for mould tool programming.” Due to our previous experiences, collision prevention was a critical factor, something OPEN MIND certainly convinced us of. Matthew Coulson from OPEN MIND provided the most efficient and productive solution with an intuitive presentation that detailed the benefits of hyperMILL over its competitors particularly well. I gave the gear selector barrel to all the leading CAM vendors and asked them to program it. “Re-designing and re-manufacturing the Hayabusa 1300cc engine to fit into a Mini meant we had to re-position the gearbox and add a reverse gear.

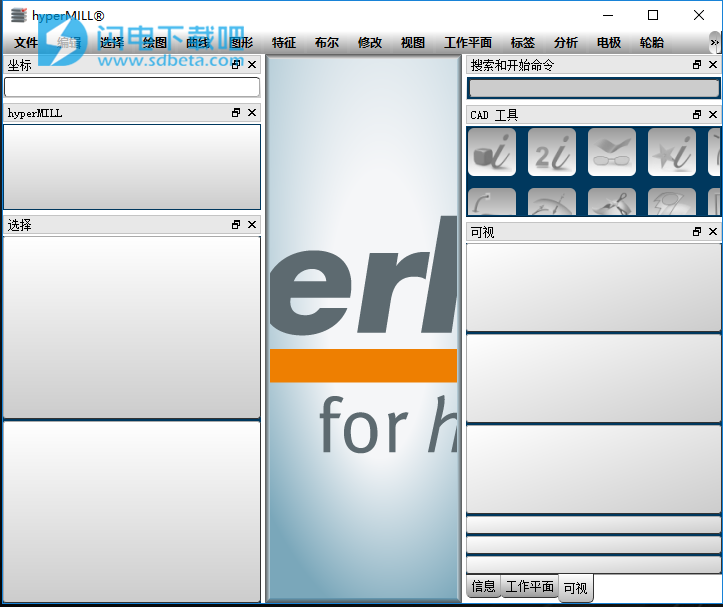

Hypermill video tutorials software#

We needed to change our CAM software and invited all the leading vendors in to present to us.”īeing an extremely experienced CAD/CAM designer and programmer, Mr Smith has in-depth experience of all leading CAM packages, coincidentally being one of the first UK engineers to be trained on hyperMILL in the mid-1990’s during his previous employment at The Hyde Aerospace Group.

We then programmed a gear selector barrel that was almost impossible with our old package. The lack of collision detection was a major cause for concern. The result was weeks without the machine whilst we installed a costly new spindle. One day we machined a mid-housing part for our Hayabusa engine and the VMX42M did a rapid traverse between two points, crashing into our fixtures and ruining the spindle.

HyperMILL Brings Anti-Collision Confidence to VetechĬommenting upon the situation prior to the arrival of OPEN MIND’s hyperMILL CAM system, Vetech’s Senior Design Engineer, Mr Andy Smith says: “Our longstanding CAD package had an integrated CAM system we were using for all our machining tasks. Designing and manufacturing complex aluminium mould tools, military sensors and the innovative Hayabusa engine, the previous CAD/CAM system was struggling to cope with component complexity. Part of the acquisition trail includes a Hurco VMX42M and a VMX30Ti machining centre with the larger VMX42M being retro-fitted with a Hurco 4th axis rotary unit two years ago.

Hypermill video tutorials manual#

The subcontract company has a plant list that includes manual and CNC machining centres, injection mould machines and test facilities. It is here the expertise of CAM developer OPEN MIND Technologies has come to the fore. Not a business to rest on its laurels, Vetech has applied its expertise to the motorsport sector, converting the Suzuki Hayabusa motorcycle engine for use in the Mark I to VII Mini motorcar produced from 1959 to 2000. This diversification has been a welcome respite for a business that has noticed a dip in European business during the Brexit process. Providing design, consultancy, subcontract manufacture and mould & die tooling, the Derbyshire business has retained Bosch as a core customer whilst branching into the military, general subcontract, electronic sensor and plastic moulding sectors. When Vetech Product Design & Development Ltd first opened its doors for business in 1994, the founders of the Buxton Company exploited their expertise in the garden equipment sector to win business from the globally recognised Bosch brand.

Pocket Rocket Goes Even Faster With hyperMILL & Hurco

0 kommentar(er)

0 kommentar(er)